We Transform Metal into Masterpieces

Craftsmanship Meets Elegance

The Perfect Finish That Every Metal Deserves

Contact for the PERFECTLY FINISHED METAL SURFACES from EmirFab

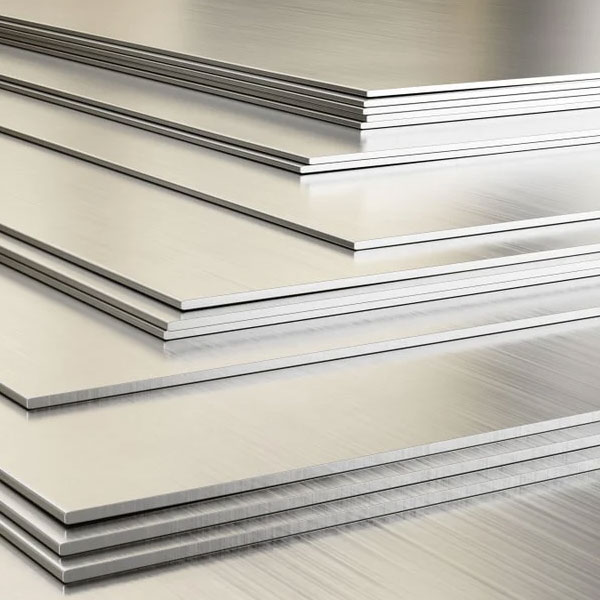

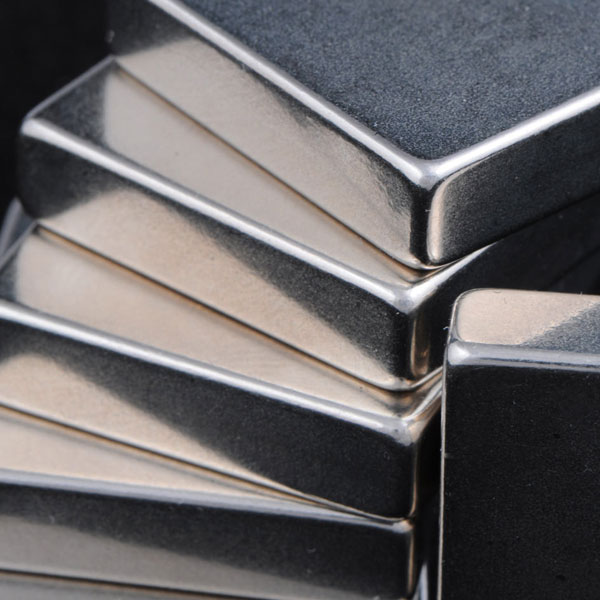

Metal Finishes

Stainless Steel Finishing

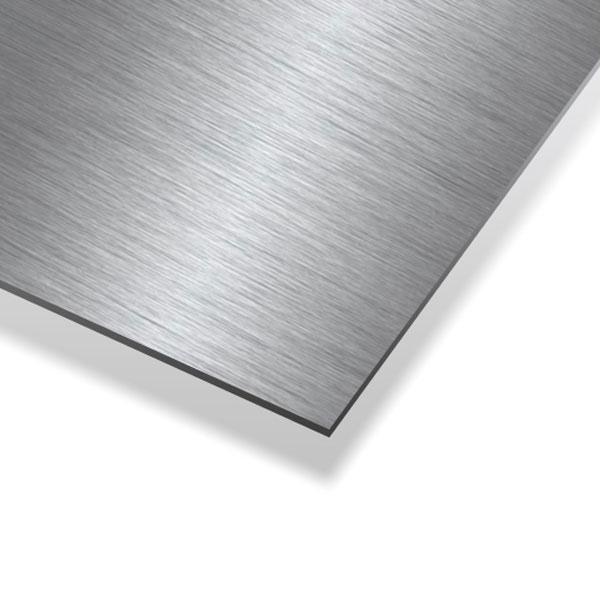

Brush Finishing

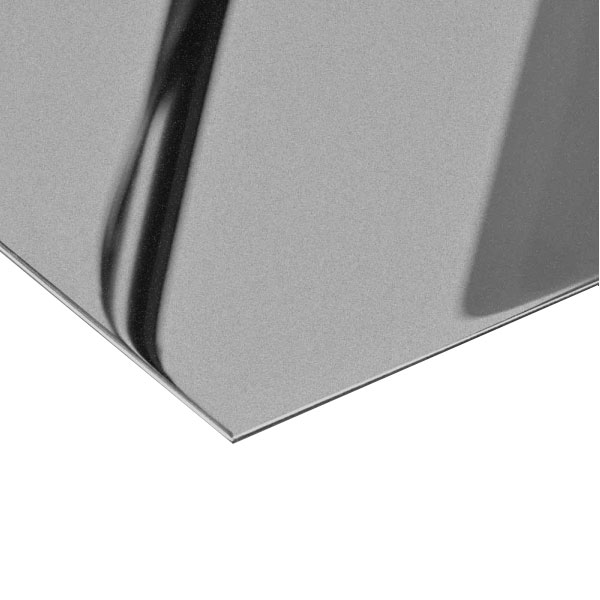

Mirror Finishing

Hairline Finishing

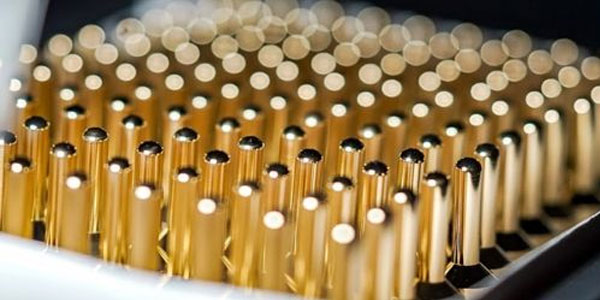

Electroplated finishing

Brass Finish

- Brushed electroplated finish

- Mirror electroplated finish

Gold Finish

- Brushed electroplated finish

- Mirror electroplated finish

Rose Gold Finish

- Brushed electroplated finish

- Mirror electroplated finish

Copper Finish

- Brushed electroplated finish

- Mirror electroplated finish

Bronze Finish

- Brushed electroplated finish

- Mirror electroplated finish

Silver electroplated finish

Nickel electroplated finish

Black Nickel electroplated finish

Antique finish

Pen gold electroplated finish

Physical Vapour Deposit(PVD)

Enhance the look of your interior with PVD technique.

Physical Vapor Deposition (PVD) is a technique used to deposit thin films of materials onto a substrate. It involves the vaporization of a solid material in a vacuum environment and its subsequent condensation onto the substrate, forming a thin film.

- Gold

- Silver

- Copper

- Bronze

- Brass

Get the perfect finish

Get you metal surfaces and structures a perfect finishing today with EmirFab

Mild Steel Finish

Surface treatment

Abrasive blasting

Sand blasting

Enhance the getup of your mild steel structures by polishing them with sand blasting

Sandblasting, also known as abrasive blasting, is a process in which a high-pressure stream of abrasive material is propelled against a surface to remove contaminants, roughen the surface, or prepare it for further treatment. It is commonly used to clean, etch, or strip paint, rust, scale, or other coatings from various surfaces, including metals like mild steel.

Bead blasting

Beautify your mild steel surfaces with the most elegant bead blasting technique

Bead blasting is a surface preparation technique that involves using fine abrasive media propelled at high speed to clean, smooth, or texture a material's surface. When bead blasting mild steel, the process helps remove rust, scale, paint, or other surface contaminants, leaving behind a clean and uniform surface.

Galvanizing

Galvanizing

Give durable sheen to your structures with galvanized mild steel

- Hot dip galvanization

- Cool dip galvanization

- Electro galvanization

Final finish

Powder coat finish

Protect your structures with the durable powder coating technique.

Powder coating is a popular finishing technique for mild steel. It provides a durable and attractive finish that offers enhanced protection against corrosion, wear, and impact.

Powder coating offers various advantages for mild steel, including excellent durability, resistance to chipping and scratching, and a wide range of color options.

Normal powder coating finish

Powder coat your metal surfaces to make it long lasting and attractive.

Normal powder coating, also known as conventional powder coating, is a widely used finishing technique for various metal surfaces, including mild steel. It involves the application of dry powder particles onto the surface, which adhere electrostatically and form a protective coating when cured.

Super durable finish (SDF)

Provide excellent protection and longevity for your Mild Steel surfaces

A super durable powder coat finish is a type of coating that provides exceptional resistance to wear, corrosion, and environmental factors. It is designed to withstand heavy use, harsh conditions, and prolonged exposure to UV radiation, chemicals, moisture, and abrasion.

Grit finish powder coat

Give your mild steel structures a textured look with grit finish powder coating

A grit finish powder coat is a type of powder coating that creates a textured or rough surface finish on metal. It is also sometimes referred to as a sandpaper finish or textured finish powder coat. The grit finish is achieved by incorporating abrasive particles or additives into the powder coating material.

Rust finish

Paint with primer

Painting with a primer on mild steel is a common practice to improve the adhesion and durability of the paint coating. Painting the mild steel surface with primer provides it with improved protection and an aesthetically pleasing finish.

Aluminium

Physical Vapor Deposit (PVD)

Powder coat

- Kynar coating (PVDF)

- Normal powder coat

- Powder coat your Aluminium surfaces to make it long lasting and attractive.

- Metallic powder coat

- Wood powder coat

- The powder coat technique exclusively for wooden surfaces

- Grit finish powder coat

- Enhance the elegance of your Aluminium structures by giving it a textured look

Anodizing

The thick oxidized layer gives you ultimate protection against corrosion and wear.

Aluminum anodizing is an electrochemical process that enhances the surface of aluminum by creating a protective oxide layer. This oxide layer not only improves the appearance of the aluminum but also provides increased corrosion resistance and durability.

Electroplated finish

Galvanized Iron (G.I)

Durability and esthetics are guaranteed with our range of Galvanized Iron works.

A galvanized iron finish refers to the protective coating applied to iron or steel surfaces through a process called galvanization. Galvanization involves coating the iron or steel with a layer of zinc to provide corrosion resistance and durability.